JIARUN BEARING HAS A WIDE RANGE OF APPLICATIONS AND EXCELLENT PERFORMANCE IN VARIOUS MECHANICAL EQUIPMENT

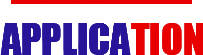

Metallurgical Steel Works

Rubber plastic machinery

agricultural machinery

construction machinery

JR BEARINGS HAVE Wide application and good performance

MORE +

Automobile manufacturing

New energy equipment

Jiarun bearing has developed and improved dozens of series and tens of thousands of specifications. Its quality and performance are in the leading position in China and reach the international level

JDB series solid inlaid self - lubricating bearing is based on metal materials, and a certain proportion and proper size of solid lubricant is arranged on the base according to working conditions。This bearing perfectly combines the high load-bearing,high wear resistance of metal and the self - lubricating performance of solid lubricant,so that it does not need oil maintenance in the use process,greatly improving the mechanical properties and reducing the maintenance cost of bearings and equipment。 According to different working conditions, we have developed different matrix materials and lubricants to meet the use of various harsh conditions, so as to achieve excellent performance。

MORE+

JDB copper sleeve is based on metal materials。 Most products will be designed and processed with different types and sizes of oil grooves and oil holes。 It is a bearing lubricated by oil supply from oil grooves。 According to different working conditions,we have developed different matrix materials to meet the use of various harsh conditions,so as to achieve excellent performance。

MORE+

SF - 1 series metal composite oil-free bearing is made of high - quality low carbon steel as the base plate, sintered spherical porous bronze powder layer in the middle, and rolled PTFE as the main lubricating material on the surface, and then processed by rolling。The bearing has excellent lubricity and good bearing capacity。 The middle copper powder layer improves the bonding strength of the plastic layer and the base plate, and at the same time,it timely transfers the heat generated during the bearing operation。 According to different requirements, we have developed a variety of materials to meet different conditions。 SF-2 series metal composite boundary lubrication bearing is a kind of lubrication material with high quality low carbon steel as base plate,spherical porous bronze powder layer sintered in the middle, POM as the main surface, and oil storage pit。 It can effectively improve the storage of oil and reduce the frequency of oil filling。At the same time,it can also bury the external invasion of dust and extend the service life of the bearing。 The copper powder layer in the middle improves the bonding strength of the plastic layer and the base plate, at the same time, it also transmits the heat generated during the bearing operation。 The bearing is suitable for grease lubrication。

MORE+

JF series bimetal composite bearing is based on high - quality low - carbon steel, and the copper alloy with low friction characteristics is sintered on the surface as the wear - resistant layer of the bearing。The surface of the copper alloy can be processed into various types of oil grooves, oil cavities,oil holes,etc。according to the use conditions。 Through sintering and extrusion,the material has a good combination strength and the best bearing capacity。The copper layer on the bearing surface can be based on the situation Choose different materials to meet the requirements of different occasions。

MORE+

FB series bronze rolling bearing is made of high - density bronze alloy plate. According to different lubrication conditions, we provide two forms of oil hole and oil hole。 Oil hole is used for grease lubrication and oil hole is used for fluid lubrication. On this basis, we further developed the G series products, which is a new structure embedded with special solid lubricant on the original bearing surface, so that it can play a better lubricity and wear resistance。

MORE+Other product series fzh (copper base), fzl (aluminum base) and FZP (resin base) steel ball cages are made of copper alloy, duralumin alloy and POM resin respectively. On the outer surface of the cages, orderly arranged holes with proper size are machined, and special holes are newly installed, and rolling bearing steel balls are inserted in the holes. By adopting the latest groove circle lock ball technology, the problem that the traditional lock ball can not completely prevent the steel ball from falling off is effectively solved. A 90 ° stop is machined at the bottom of the hole to make the steel ball rotate freely in the hole without falling off. Because the diameter of the steel ball is larger than the wall thickness of the retainer ring, the steel ball is higher than the inner and outer surface of the retainer ring when in use, and directly contacts with the matching hole and shaft, so that the matrix (retainer ring) floats in the middle, and the difference between the radius of the matching hole and shaft is smaller than the diameter of the steel ball, that is to say, the matching of the steel ball and it is interference fit, with high matching accuracy, and the relative movement of the shaft and hole is flexible. Is to keep the circle of updated products. Fu powder metallurgy oil bearing is made of metal powder, pressed by mould, sintered at high temperature and shaped. It has fine and evenly distributed pores and forms oil-bearing state after vacuum impregnation of lubricating oil. The product has the characteristics of short-term non oiling, low cost, high accuracy of internal and external diameter dimensions. According to different materials, it can be divided into the following three types: fu-1 copper base oil bearing, fu-2 iron base oil bearing, fu-3 copper iron mixed base oil bearing.

MORE+

Based on trust, win with quality, develop innovation, strengthen and expand

10year+

Founding time500home+

Serving customers800wpiece+

Annual sales volume1,500w

registered capital

Zhejiang Jiarun Bearing Technology Co., Ltd. (formerly known as Jiashan Jiarun Sliding Bearing Factory) is located in the National Economic Development Zone of Jiashan County, Zhejiang Province. The company is a high-tech enterprise that integrates research and development, production, and sales of various self-lubricating bearings, oil-free bearings, sliding bearings, and other series of products. The company has a professional team, advanced and complete equipment, scientific and complete management, and product quality and performance have reached the leading level in China. The company's business is spread all over the world, and is……

workshop

hall

office

office

Meeting Room

reception room

Technology Department

Technology Department

warehouse

warehouse

workshop

workshop

workshop

workshop

workshop

workshop

graphite

graphite

Finishing bearing inner and outer circles

Machining of threaded holes of copper sleeve

Machining the graphite hole of sliding plate

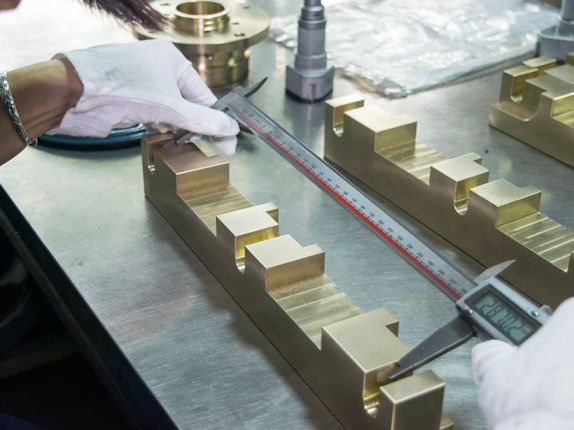

Finished product inspection

Bearing dimension inspection

Dimension inspection of sliding plate

Make materials strictly according to customer requirements or national standards, and provide material reports

Make materials strictly according to customer requirements or national standards, and provide material reports

Material assurance

We have exquisite technology, excellent equipment, strict control and comprehensive inspection to ensure that every product is qualified

We have exquisite technology, excellent equipment, strict control and comprehensive inspection to ensure that every product is qualified

Accuracy assurance

Support customization and development of non-standard products and special products to meet different needs of customers

Support customization and development of non-standard products and special products to meet different needs of customers

Personalized custom

Follow up the whole process of sales and production, and the system automatically arranges orders to better meet customer delivery time

Follow up the whole process of sales and production, and the system automatically arranges orders to better meet customer delivery time

Prompt delivery

Real professional manufacturers, continuous innovation and optimization, continuous improvement of production efficiency, only to provide competitive prices

Real professional manufacturers, continuous innovation and optimization, continuous improvement of production efficiency, only to provide competitive prices

Price advantage

Provide all-round professional services before, during and after sales at home and abroad

Provide all-round professional services before, during and after sales at home and abroad

Comprehensive service

2020 North China auto parts exhibition, northwest Auto Parts Exhibition and national truck parts exh

2020 North China auto parts exhibition, northwest Auto Parts Exhibition and national truck parts exh

2020-02-11In March next year, Zhengzhou machine tool exhibition will rekindle the purchasing tide and accumula

2020-02-11Bearing localization of 3300 plunger pump for petrochemical machinery propulsion

2020-02-11Htfe 2020 China International Hardware tool and fastener industry exhibition will be held in Wuhan i

2020-02-11China's first set of wind power sea mounted high-precision bearing induction equipment Shiyan came o

2020-02-11Luoyang LYC bearings: research and development of advanced bearings to help "along the road" constru

2020-02-11