China's first set of wind power sea mounted high-precision bearing induction equipment Shiyan came o

On November 26, the good news came from Shiyan economic and Technological Development Zone. Shiyan gaozhoubo technology industry and Trade Co., Ltd. successfully developed the first set of high-precision bearing induction equipment used in the production and processing of wind power equipment bearings in China.

The successful development of this equipment not only completely breaks the technical barriers of foreign countries to the processing and manufacturing of wind power high-precision bearings, but also promotes the development of China's offshore wind power industry, which is a "great power heavy weapon"!

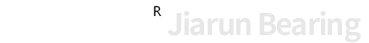

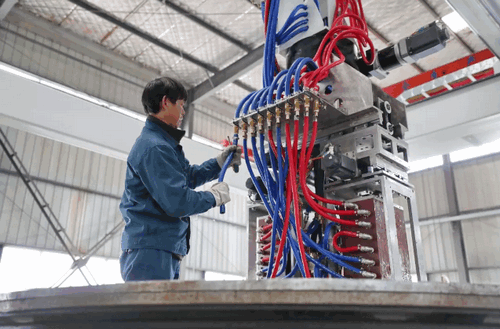

In the afternoon of the same day, the reporter saw in the Shiyan high frequency production workshop that a large high-precision bearing induction equipment with a length of 10 meters, a width of 12 meters and a height of 4 meters occupied a quarter of the workshop space, and the workers were doing the final equipment debugging. It is reported that the equipment will be delivered to vision Energy Technology Co., Ltd. in the near future.

Wind energy is recognized as a clean and renewable energy in the world. Its installed capacity accounts for 12% of the total global power generation, while the installed capacity of offshore wind power only accounts for 20% of the global wind power generation. As one of the key components, high-precision bearing has a vital impact on the efficiency, safety and life of wind power equipment. As the offshore wind power equipment is restricted by environmental factors, the maintenance cost even exceeds the price of the whole power generation equipment. As a vulnerable part of the equipment operation, the accuracy and service life of the bearing basically determine the service life of the offshore wind power equipment.

It is understood that the power control accuracy of the equipment should be less than 1%, the positioning error of the machine tool should be less than 0.05mm, the constant temperature cooling error should be less than 3 ℃, and the maximum diameter of the processing bearing should be 8m These strict technical requirements are an insurmountable "gap" for the global wind power offshore equipment manufacturers, especially the processing and manufacturing equipment of bearing, the most critical component of offshore wind power equipment, which has been monopolized by a German enterprise for a long time. The bearings of offshore wind power equipment in China can only rely on imports.

Shiyan gaozhoubo technology industry and Trade Co., Ltd. is a high-tech enterprise dedicated to the R & D and manufacturing of automatic induction equipment. In 2014, it started to cooperate with vision Energy Technology Co., Ltd., which is mainly engaged in the development and sales of intelligent fans around the world. Aiming at the high-precision bearings required by wind power offshore installation, it developed large-scale high-precision bearing induction equipment of wind power offshore installation. After five and a half years, Shiyan gaozhoubo finally succeeded in research and development.

Its main core technologies are: automatic clearance of rotary table, no back clearance of rotary table in forward and reverse direction; electronic automatic tool setting; electronic automatic tracking of workpiece without contact. The equipment uses the wind power sea mounted induction heat treatment equipment composed of digital intelligent induction heating power supply and high-precision multi axis linkage machine tool to heat treat the large-scale and high-precision bearings, adopts the processing technology of the four ends of the gantry. Compared with the bearing processing equipment of the double ends of the gantry in German Enterprises, the working efficiency is doubled, and the processing accuracy is obviously superior to the foreign manufacturing technology.

According to he Zhongyong, general manager of Shiyan gaozhoubo science, industry and Trade Co., Ltd., the localization of China's offshore wind turbines has just started. The processing and manufacturing equipment for high-precision bearings of wind power equipment is monopolized by German enterprises, with a price of up to $50 million. However, the price of our independently developed high-precision bearing sensing equipment is only 10 million yuan.

This time, vision Energy Technology Co., Ltd. ordered 6 sets of high-precision bearing induction equipment in Shiyan. The head of the company said that the localization of high-precision bearing induction equipment will comprehensively promote the localization of high-precision bearing production batch of wind power equipment, completely change the situation that China's high-precision bearing relies on imports, and create conditions for the large-scale development of China's offshore wind power.